Into the Glass

Gain expert insights into the world of glass processing with Mika Eronen

Everything You Did Not Know About Soda Lime Silica Glass Properties

Properties Glass is a material with some rather unique and amazing properties. Due to these properties, the processing of glass and the methods used to manufacture products from it are very different from those used to cut and shape other

Understanding and Controlling Anisotropy in Heat-Treated Glass

Learn how anisotropy, a natural feature of heat-treated glass, is influenced by design choices, coatings, and glazing configurations. With modern in-line inspection and real-time process control, manufacturers can actively manage and reduce anisotropy, ensuring consistent visual quality in tempered glass.

Setting Up Screen Printing for Quality Automotive Glass

Overview Modern automotive windshields introduce significant challenges in glass manufacturing. Proper machine setup and parameter optimization are crucial for high-quality screen printing. Misalignment, inadequate setup, or incorrect machine adjustments can lead to quality issues that may go unrecognized by production

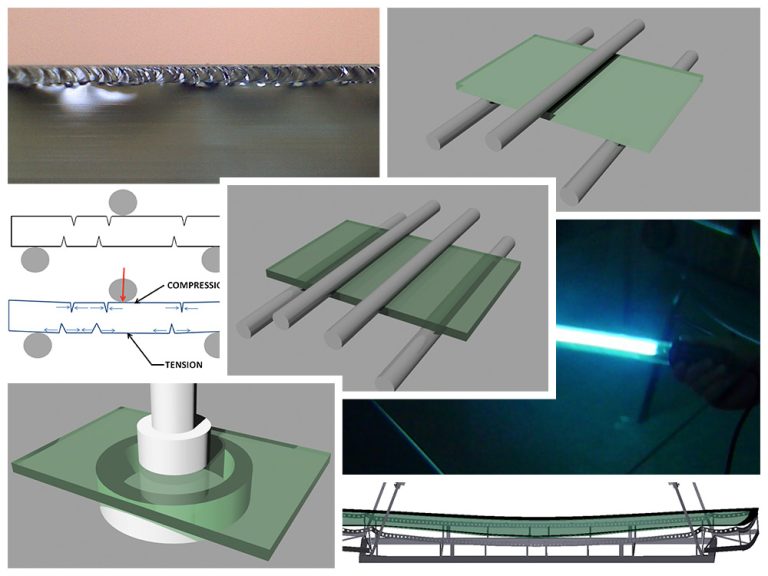

The Complex Reality of Laminated Glass – Observations from Real-World Production

Introduction – Why Lamination is a Critical Step In this article, I share field-based observations on laminated glass manufacturing gathered from around the world: recurring pitfalls in production, how to identify them, and how they can be resolved. The writing

How to Optimize Energy Efficiency in Safety Glass Manufacturing

Amid the worst socio-economic and geopolitical crisis of modern history, the glass industry is also faced challenging times. Energy-saving actions in the glass industry are at the core of sustainable manufacturing operations. The different types of glass, and interlayer materials

Tempering Troubleshooting

BOWING Cause and countermeasures: 1. Heating balance: 2. Quench air balance BI-STABLE BOW Cause and countermeasures: 1. Hot edges and cold center CHILL CRACK Possible Cause and countermeasures: WHITE HAZE Possible Cause and countermeasures: QUENCH BREAKAGE Cause and countermeasures: IRIDESCENCE

Achieving Superior Optical Quality in Windshield Bending

Overview Producing high optical quality and a smooth sagging profile for windshields requires precise process control, especially given modern design demands like large size, deep sagging, asymmetric glass thickness, colored float glass, coated glass, special glass types, extensive printing, and

Bending Mold Tooling Basics

Bending Mold Tooling – Essential for Quality Production High-quality mold tooling is critical to producing top-tier windshields. Many manufacturers struggle to innovate or maintain quality due to gaps in mold (a.k.a. skeleton ) tooling expertise. Successful windshield bending depends heavily

Gravity Bending: Essentials of Heating Element Configuration (HEC)

Overview Designing the ideal heating element configuration (HEC) for gravity bending requires understanding of infrared (IR) heating physics and the specific product parameters. A well-designed HEC achieves the required glass shape efficiently, with high quality, and reliably reproduces results. Core

Ice Flower Lamination Process Defect – Prevention and Control

The introduction of acoustic PVB interlayers for laminated glass has provided improved sound insulation to glazing solutions, both to automotive and architectural glass, but also brought unique manufacturing challenges. For acoustic PVB it is the defect known as ice flower