Anisotropy in heat-treated glass has long been one of the most complex topics in glass development. What once required extensive effort is now more manageable thanks to collaboration among industry stakeholders, leading to standardization, advanced diagnostic tools, and improved in-line inspection systems. These advancements enable better-informed decisions from the design phase through to production and quality control.

The Role of Design in Anisotropy Visibility

While standards do not restrict anisotropy, its perception plays a significant role in project outcomes:

- Standards and Expectations: Anisotropy is recognized as a natural feature of heat-treated glass. However, the expectation for flawless façade aesthetics makes early design decisions critical, particularly during specification.

- Impact of Coating Properties: Saint-Gobain’s σQM parameter is a valuable tool that quantifies how coatings influence visible anisotropy. It measures color shifts under lighting conditions that highlight stress patterns, helping designers select coatings that maintain visual consistency after tempering.

Coating Behavior and Its Effects

Different coatings behave uniquely in relation to anisotropy:

- High VLT & Low LRo Coatings: These coatings typically show less visible anisotropy for the same level of optical retardation. However, they increase the importance of tempering quality in the inner panes of insulating glass units (IGUs).

- Low VLT & High LRo Coatings: In this case, the outer pane’s tempering quality has the greatest impact on appearance, while the inner panes contribute less.

Complexity in Multi-Pane Configurations

Anisotropy visibility becomes more complex in double or triple glazing systems:

- Pane Composition: Using tempered inner or middle panes can amplify anisotropy effects. An annealed middle pane can help reduce visibility by limiting the transmission of these effects, while a tempered one adds its own stress patterns.

- Mismatch Between Single-Pane and IGU Results: Low retardation in a single tempered pane does not guarantee low anisotropy in the final IGU. Several factors influence the outcome:

- Coating Interaction: High VLT / low LRo coatings allow inner-pane anisotropy to be seen, while high LRo coatings can obscure it.

- Pane Position and Thickness: The location and thickness of each pane affect light paths and polarization.

- Multiple Stress Patterns: Each tempered pane contributes its own stress distribution, which can combine or interfere visually.

- Lighting Conditions: Polarized light from the sky or surroundings can enhance the visibility of anisotropy.

Conclusion at the Design Stage: Controlling visible anisotropy requires more than just optimizing the tempering process. It begins with informed material choices and design considerations, combined with a deep understanding of how each layer in the glass assembly interacts.

From Complexity to Clarity: Real-Time Control in Tempering

Anisotropy in tempered glass is not simply an unavoidable outcome—it can be actively controlled in real time. Once the glass enters the tempering line, process monitoring and real-time adjustments become essential for managing and documenting measured anisotropy.

The Role of Inspection Technology

Before the introduction of commercial inspection systems, anisotropy was a challenging and time-consuming issue. The development of these technologies has significantly advanced understanding of how tempering conditions affect anisotropy. Industry-wide collaboration in the early 2020s further supported this progress through improved standardization.

Real-Time Measurement with In-Line Inspection Systems

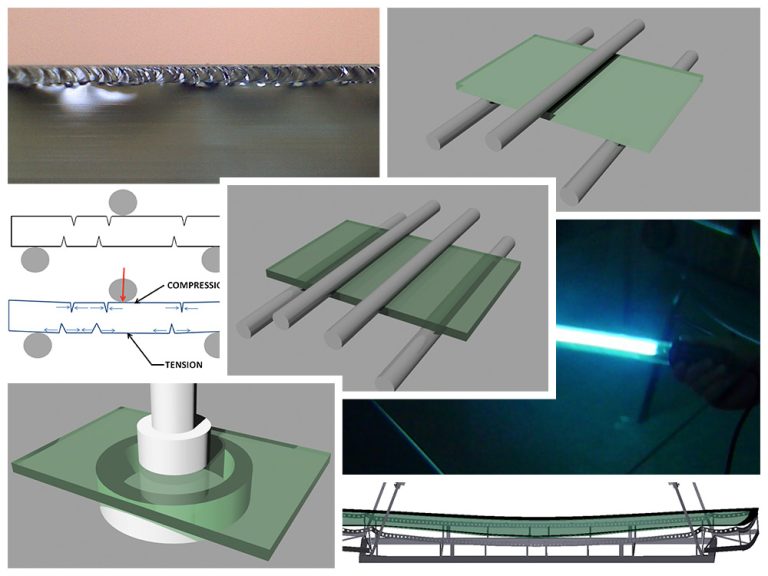

Modern in-line anisotropy inspection systems measure optical retardation immediately after tempering, generating accurate retardation maps in real time. These maps allow manufacturers to:

- Detect non-uniform quenching, such as uneven airflow that causes stress stripes or spots

- Identify roller-induced stress patterns, including cross patterns from spiral-wound roller contact

- Classify tempered glass into A, B, or C optical retardation classes according to DIN SPEC 18198:2022

- Record optical retardation data for each pane for quality control purposes

Beyond anisotropy, these systems also detect roller wave, edge lift, coating defects, and surface imperfections—giving operators a comprehensive view of product quality. Even edge stress can be measured.

Operational Control Through Live Imaging

With access to live imaging data, operators can:

- Adjust furnace heating zones and convection balance to maintain uniform surface and core temperatures

- Control quench airflow to ensure consistent cooling

- Modify loading patterns

- Validate process changes to confirm improvements in optical retardation

Process Adjustments to Minimize Anisotropy

Typical tempering process modifications include:

- Heating the glass more slowly and for a longer duration

- Using the longest possible oscillation length during heating

- Applying variable oscillation stop points

- Slowing the transfer indexing to the quench to delay the first oscillation point

Final Considerations

Even with optimal scanner imagery, an IGU may still exhibit visible anisotropy due to glass type properties and site-specific installation variables. This underscores the importance of integrating design and manufacturing efforts from the outset.

By leveraging in-line scanners and real-time process control, anisotropy management shifts from a reactive approach to a proactive strategy—ensuring higher quality and more consistent visual outcomes in tempered glass.

Learn more about OSPREY®25 optical inspection system here: https://www.glassquality.com/products/osprey