BOWING

Cause and countermeasures:

1. Heating balance:

- Water holding: Reduce top temperature (convection or IR- heaters)

- Water shedding: Increase top element power ( convection or IR- heaters)

2. Quench air balance

- Water holding: Increase top quench pressure

- Water shedding: Increase bottom quench pressure

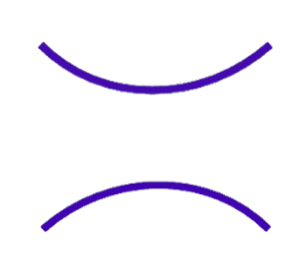

BI-STABLE BOW

Cause and countermeasures:

1. Hot edges and cold center

- Decrease Furnace temperature and/or increase cycle time

- Reduce edge heating

- Increase convection pressure

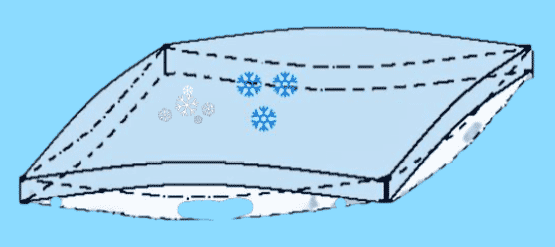

CHILL CRACK

Possible Cause and countermeasures:

- High quench pressure setting -> Reduce

- Too cold exit temperature -> Inrease

- Moisture in quench air -> Reduce air intake outside

- Glass stopped during quenching

- Excessive blowback to furnace -> Check

- Cover last furnace rollers with Kevlar

WHITE HAZE

Possible Cause and countermeasures:

- Excessive Bottom Temperature -> Reduce (roller bed temperature)

- Varying temperature conditions due to incosistent loading -> Run consistent full loads

- Bowing at heating ->Adjust heating:

a. Haze at edges decrease top heating

b. Haze in center parts of glass increase top heating - Roller contamination -> Clean the roller bed

QUENCH BREAKAGE

Cause and countermeasures:

- Edge work:

- Review and correct cut & grind process

- Glass oscillation stop at quench:

- Review and adjust quenching conditions

- Glass exit temperature:

- Low furnace exit temperature -> increase heating time

- Quench air cool or moist:

- Reduce outdoor air intake

- Glass thickness:

- Measure glass thickness

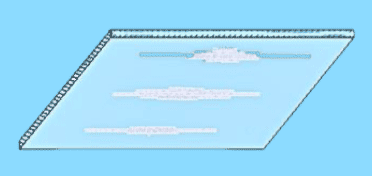

IRIDESCENCE

Cause and countermeasures:

- Furnace conditions:

- Decrease Furnace temperature

- Increase the oscillation lenght to max

- Quench conditions:

- Nozzle distance & field temp condition

- Quench pattern test -> clean?

- Maximum oscillation time to first stop.

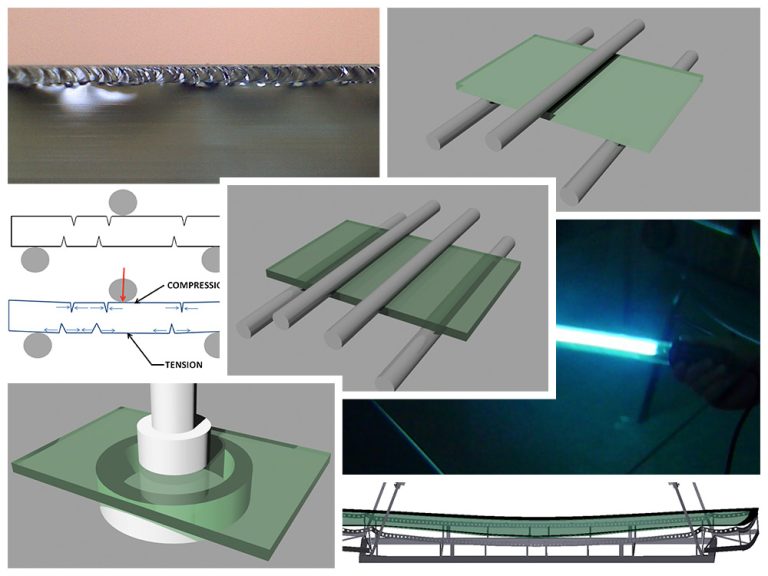

ROLLER DISTORTIONS

Possible Cause and countermeasures:

- If ‘wave’ peak to peak=roll spacing distance:

- Excessive glass temperature at exit

- Glass “stop” on oscillation reversals

- If wave peak to peak=circumference of the roller

- Twisted roller in furnace or quench

- Glass End Kinks

- Check furnace-quench levelling.

FRAGMENTATION ISSUES

Possible Cause and countermeasures:

- Excessive Fragment Count:

- Reduce quench pressure or glass temp

- Low Fragmentation:

- Increase quench pressure or/and glass temp

- Elongated spline-type fragments:

- Review heating conditions ->uniform temp

- Review quench conditions, quench nozzle field condition, top-bottom cooling rate (balance).