Overview

Modern automotive windshields introduce significant challenges in glass manufacturing. Proper machine setup and parameter optimization are crucial for high-quality screen printing. Misalignment, inadequate setup, or incorrect machine adjustments can lead to quality issues that may go unrecognized by production teams, who often adjust settings arbitrarily.

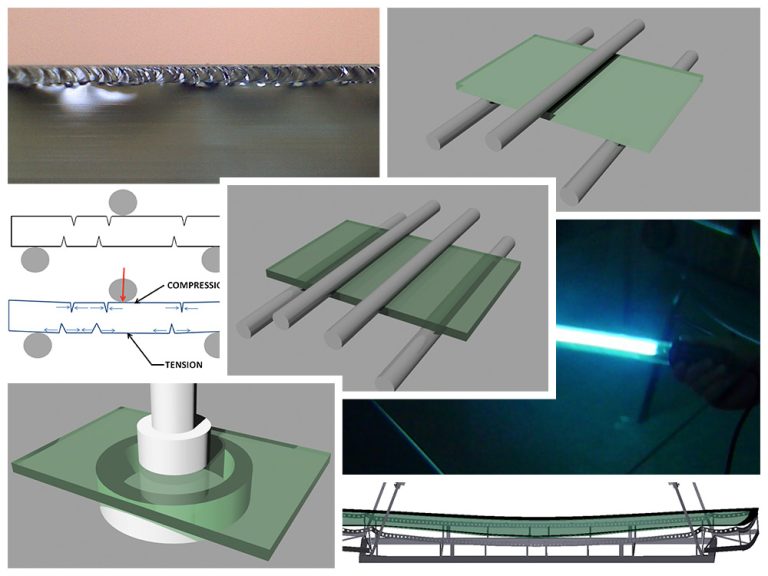

Key Machine Types

- Semi-automatic machines: Require manual glass centering. Setup focuses on controlling peel-off distance to balance squeegee pressure, avoiding excessive ink or weak contact.

- Fully automatic machines: Include conveyor-driven tables, making table flatness a critical factor. Regular adjustments ensure consistency across the glass surface.

Core Setup Parameters

- Table flatness and smoothness – Essential for even ink application.

- Peel-off and Off-contact – Maintain an optimal lift distance post-squeegee contact for precision.

- Squeegee Pressure and Flexibility – Set between 70°-75° to control ink thickness; monitor wear and replace as needed.

- Ink Wet Thickness – Target 25 µm ± 2 µm for consistent results through subsequent processing.

Maintenance Practices

- Regularly inspect squeegees and flood blades for nicks and height issues.

- Use high-quality, resilient squeegee rubbers with appropriate hardness for uniform application.

- Keep the printing room dust-free and regulate temperature (22°C ± 2°C) and humidity (52% ± 7%).

Quality Control Measures

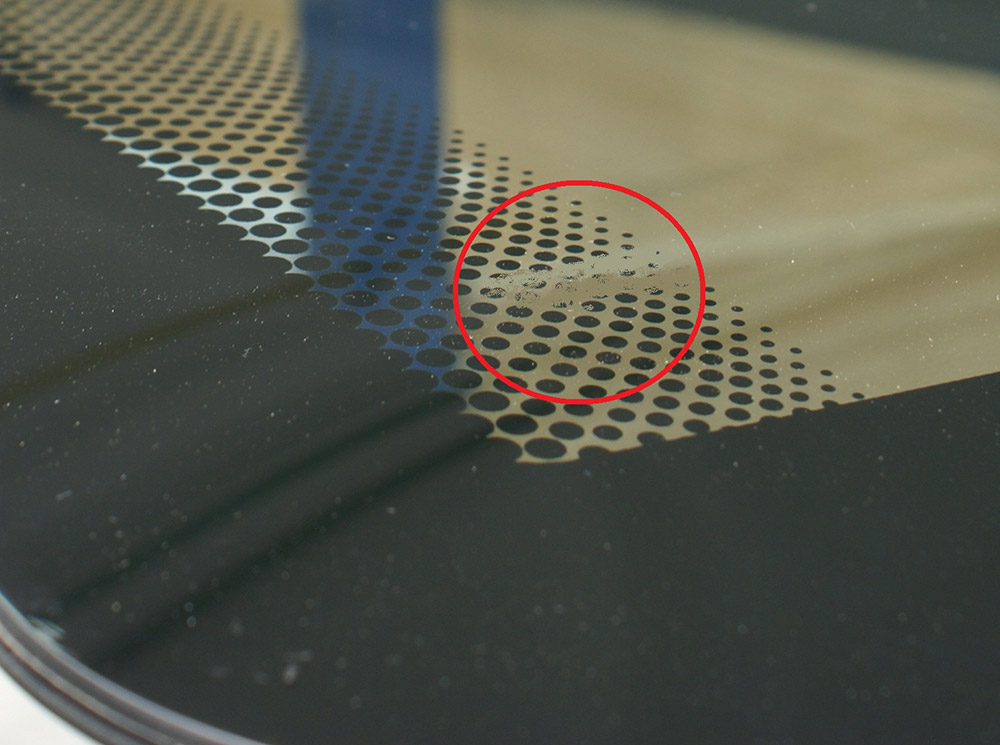

- Inspect printed glass against uniformity benchmarks, checking for:

- Ink Thickness: Essential to avoid transparency issues after bending.

- Clear Edges: Ensure consistent margins, typically 2 mm around edges.

- Printing Defects: Star lights, transparency flaws, and pinholes must be detected early to avoid value loss.

Consistently monitoring these parameters helps ensure high-quality, defect-free screen printing, meeting rising industry standards and client expectations.

Conclusion

Effective screen printing requires attention to machine setup, environmental controls, and stringent maintenance. Implementing standard protocols enhances production reliability, reduces waste, and supports the manufacturing of quality automotive glass.